At Metelmex, we understand the importance of having the highest quality raw materials in order to ensure long lasting products and finishes. This is why we have created a metallographic lab of our own to verify the chemical composition of our raw materials.

Steels are iron-carbon alloys with considerable concentrations of other alloying elements. In the global market, there are thousands of different steels made up of several compositions and/or thermal treatments. Therefore, it is important to ensure their real composition.

In our Metallographic lab, we also offer Steel Chemical Analysis to our customers and suppliers. This analysis focuses on determining the amount elements existing in a sample. Elements such as: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, nickel, aluminum, cobalt, copper, niobium, titanium, vanadium, tungsten, lead, tin, magnesium, arsenic, zirconium, bismuth, calcium, cerium, antimony, tellurium, boron, zinc, lanthanum, and iron.

The results are given in percentages units, for example:

DIFFERENT ANALYSIS PROVIDED BY METELMEX METALLOGRAPHIC LAB.

CHEMICAL ZINC ANALYSIS

The most important uses of zinc are: to alloy to other metals and to protect other metals as a coating.

METELMEX provides Chemical Analysis to analyze a sample whose content is zinc. This type of analysis helps to determine the amount of aluminum, copper, lead, tin, cadmium, iron, indium, magnesium, manganese, nickel, antimony, titanium, chromium and thallium that exists in a Zinc sample.

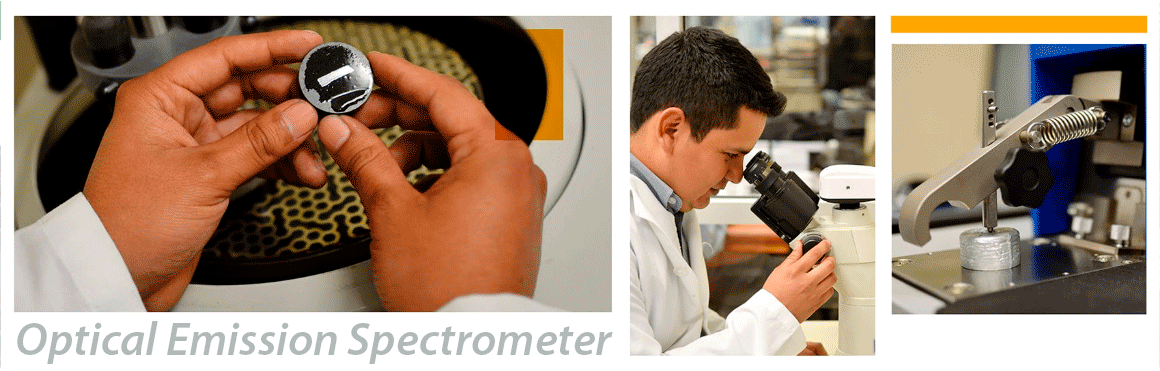

CHEMICAL ANALYSIS BY OPTICAL EMISSION OR SPARK SPECTROMETRY

This type of analysis is used to determine the percentages of the chemical elements that exist in a sample. This method consists in detecting the characteristic wavelength of each of these elements when a spark excites their electrons.

The base (Fe) and (Zn) Chemical Analysis can be carried out in our laboratory.

Spectro Equipment, which is innovative and adaptable, is used in a wide variety of fields, including metallurgy, environmental, as well as quality control.

In METELMEX we are members of the Mexican Association of Galvanizers (Asociación Mexicana de Galvanizadores, A.C. AMEGAC). Therefore, we are ready to provide you with the professional advice and information you need. At Metelmex, we work under the highest quality standards, always envisioning humanism and respect in all our practices.

If you want to know more about how our Metallographic lab can help you to your projects, contact us for personalized advice. That way we can offer the options that most suit your project’s specific needs. Remember that we complied with certifications and manufacture grates according to the most important quality standards.

To know more about our history and service visit our YouTube Channel.

Español

Español