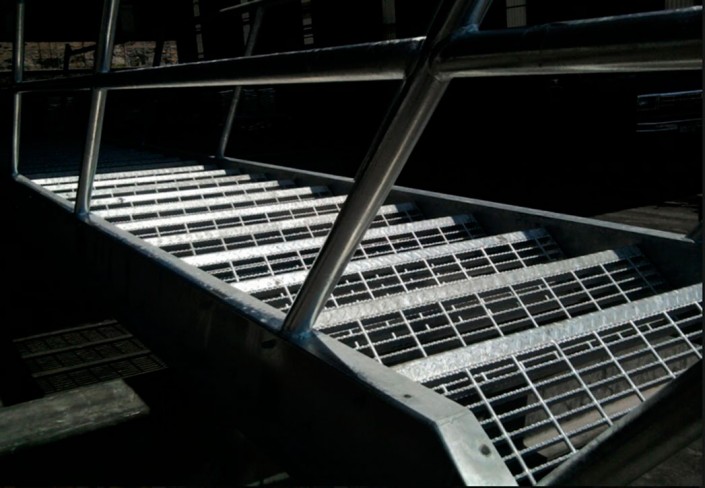

Commonly known as Stair Treads and mainly used in industrial plants. When a project includes in its structure several levels (floors), stairs normally come out as the best option, also contributing benefits such as an easy installation, low costs, customization according the area and almost a null maintenance.

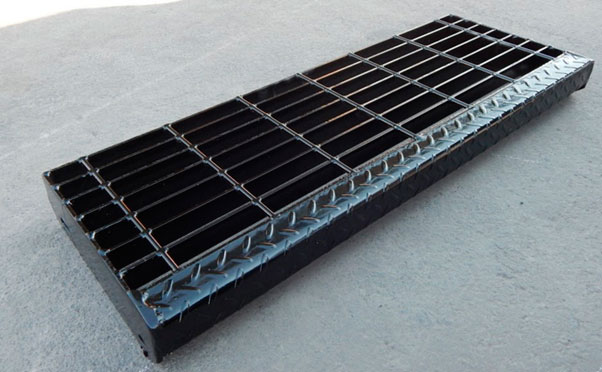

Depending on the project’s purpose Grating Stair Treads offer smooth or serrated (non-skid) surfaces; measure 8-½”, 9-¾”, 11”, or can be custom fabricated. As for the finish, depending on the environment they will be exposed: plain steel, anti-corrosive black paint or galvanizing. However to ensure greater corrosion resistance is recommended to always galvanize any steel product.

Benefits of Steel Bar Grating Stair Treads:

- Safety and Resistance. Offer non-skid surface which decreases possibilities of accidents inside the plant.

- Maintenance Savings. Since they are made of steel and not cement or concrete, bar grating stair treads do not break or crack so easily eliminating maintenance costs.

- No Cleaning Required . Since stair treads are made of steel bar grating; fluids, gases and other substances are able to pass through.

- Allow Fluids Flow. Eliminate possibilities of flooding and slippery floors that can be dangerous to transiting personnel.

- Gas passage. Prevent accumulation of gases that may cause poisoning or visibility problems inside the plant.

Take advice with the experts!

Español

Español