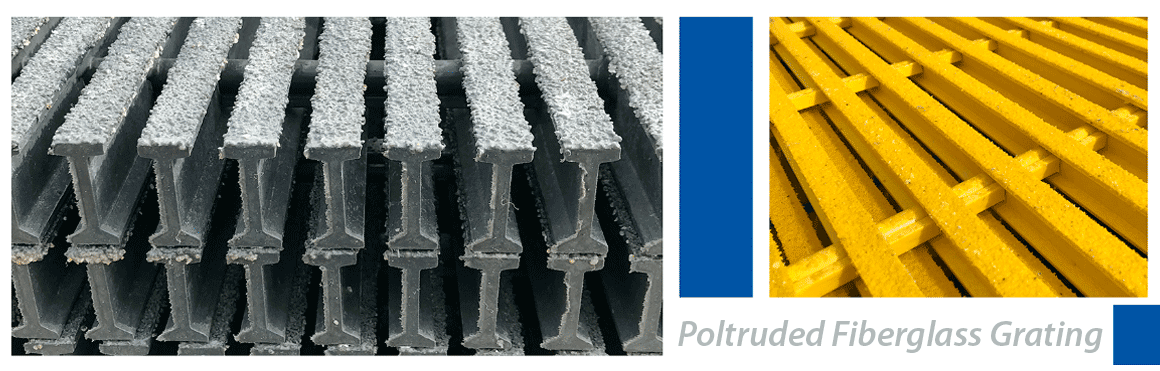

Our Pultruded Fiberglass Grating is manufactured with fiberglass threads and coatings that are guided into a resin bath where they are later subjected to a hot metal die that takes the shape of the desired screed. The assembly of the stiffening rods consists of introducing them into the type “I” screeds and then locking them and thus guaranteeing the distance between screeds.

This grating contains a high percentage of fiberglass so it provides durability and a high load capacity. It is the ideal solution for covering very long gaps.

Important Data about the Pultruded Fiberglass Grating

Advantages:

- High Uni-Directional load capacity

- Anticorrosive

- Chemical resistant

- Free of manteniment

- Light

- Non-Slippery

- UV resistant

- Insulating

- Easy to install

- Fire retardant

Common Applications:

- Water treaters

- Food Industry

- Petrochemical Industry

- Chemical or acid plants

- Pool areas

- Docks

Available Resins:

- Polyester

- Vinylester

Available Surfaces:

- Non-Slippery

Español

Español