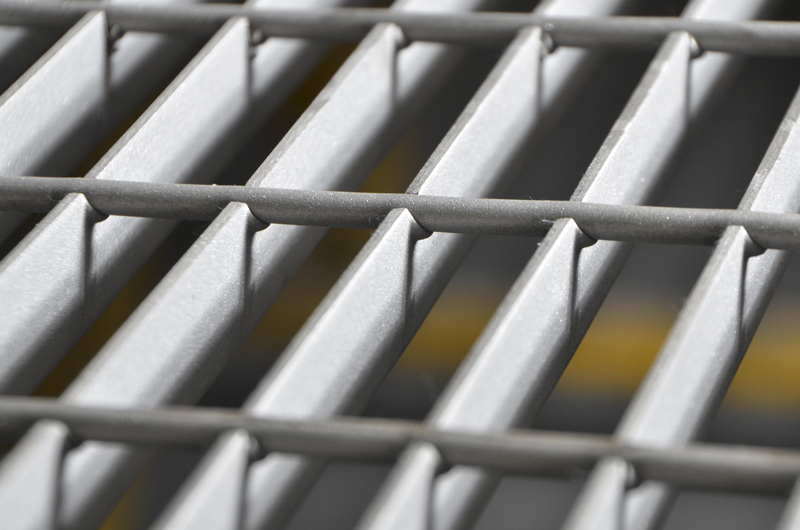

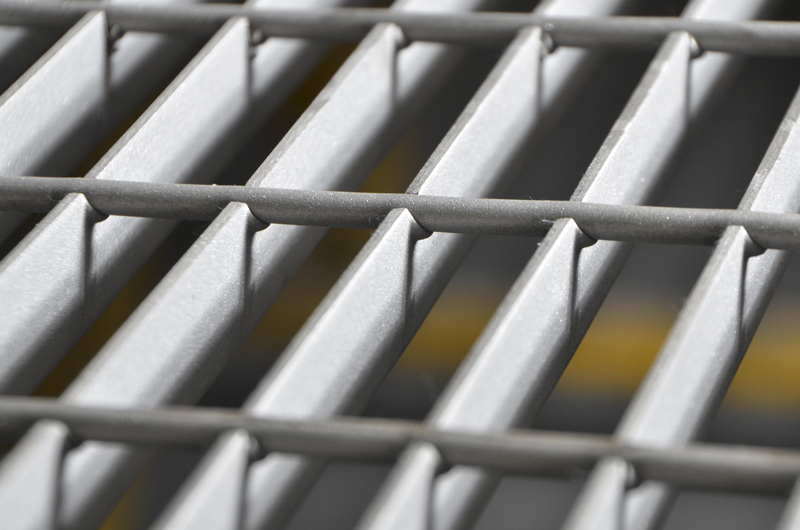

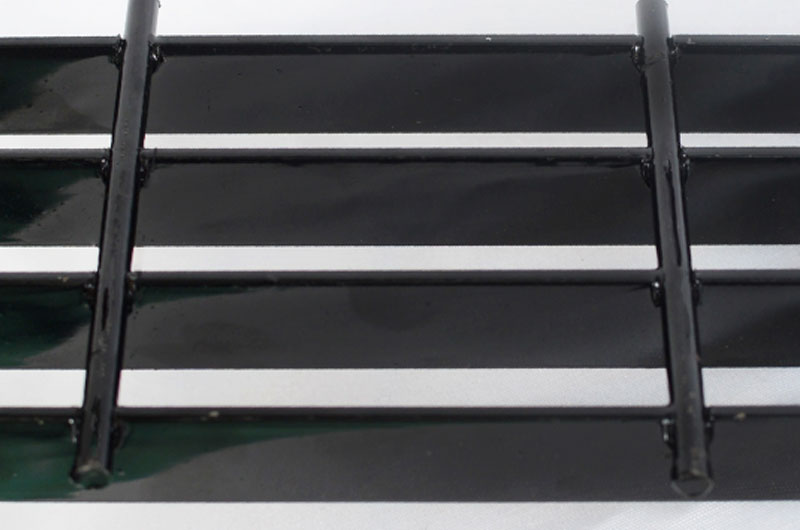

Our Steel Bar Grating is manufactured through the forged welding process, which consists in welding steel cross rods to perpendicular and equidistant bearing bars. This is achieved through high current and high mechanical pressure discharges, fusing the molecular elements of both components without placing filler material, as it occurs in the arc welding process. The forged welding process guarantees an homogeneous product of high quality and resistance.

There are different types of Electroforged Industrial Grating or Steel Bar Grating that are linked to different construction purposes such as:

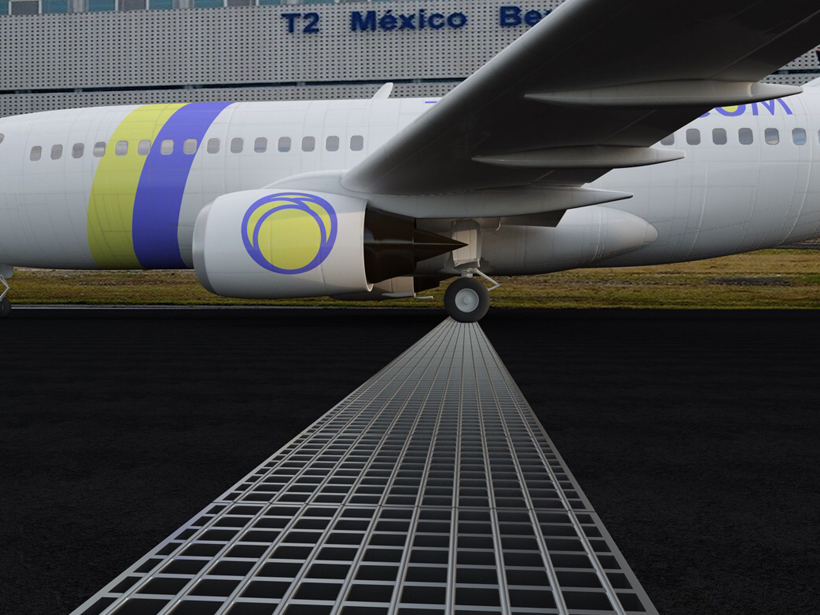

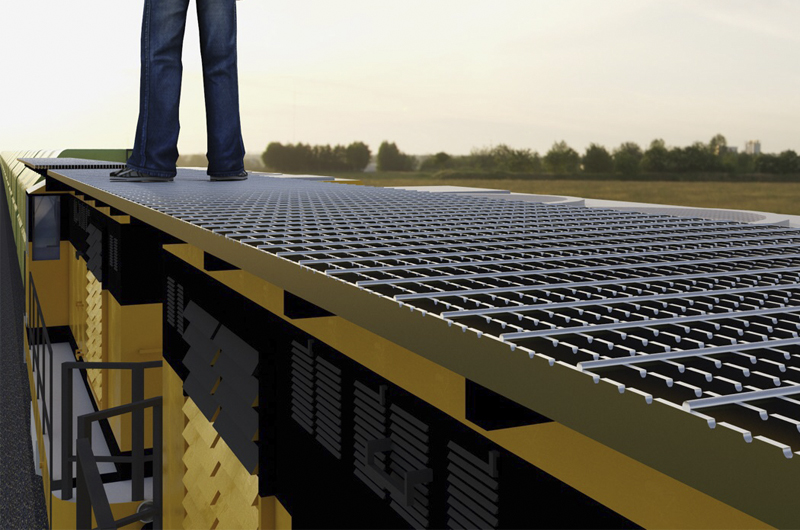

Heavy Duty Grating: Mainly used in airports and locations where very heavy vehicles pass through.

Stainless Steel Grating: It is also used in food processing plants or in environments where sulfates or acids are present.

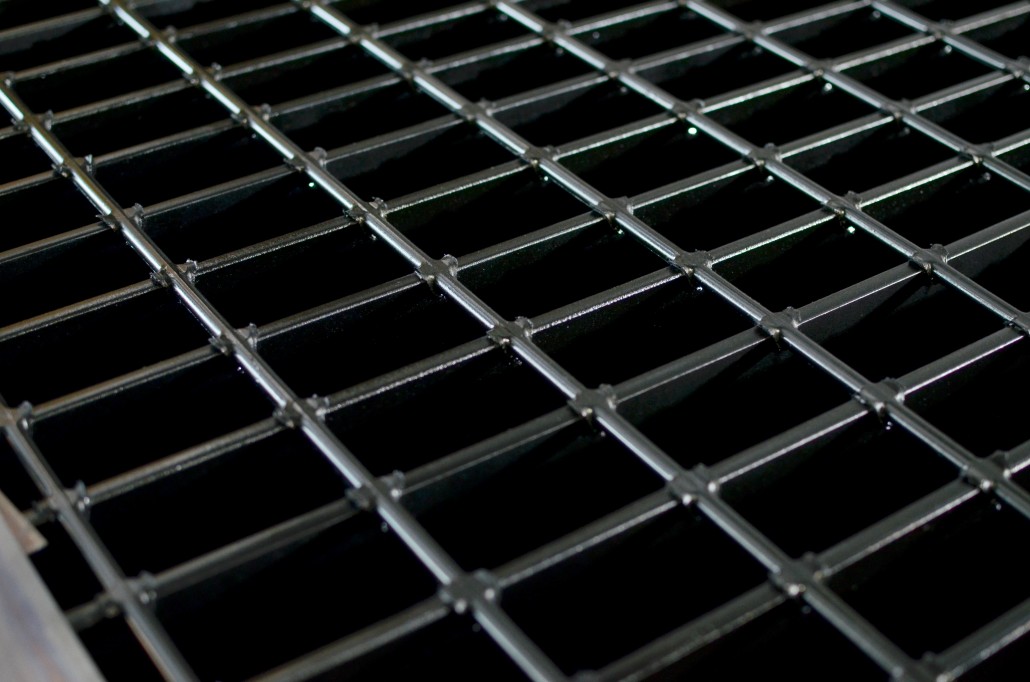

Galvanized Grating: It is suitable for all types of uses; its galvanized finish guarantees a useful life of up to 60 years, making it an excellent product.

Railway Car Grating: It is important to note that this service must be certified by AAR M-1003.

Architectural or Ornamental Grating: It is mainly used in products such as steel benches, balconies, perimeter fences, residential fences, and building facades.

In this sense, it’s important to highlight that for any project, not only is the quality and durability of the different materials used important; it’s also important to consider their design, since this, in conjunction with the finishes and colors, lends aesthetic appeal to the building. Cut-to-size grating is an excellent option for achieving both aesthetic and practicality.

We manufacture our Steel Bar Grating based on the most strict quality standards.

If you’re looking for a great solution and choosing the best type of Electroforged Grating for your project, it’s essential to understand your specific needs. Contact our experts for advice and to ensure a safe and efficient investment. Invest in quality and protect your entire industrial infrastructure!

Visit our YouTube channel to learn more about Metelmex and its history of service.