What does Steel Bar Grating is?

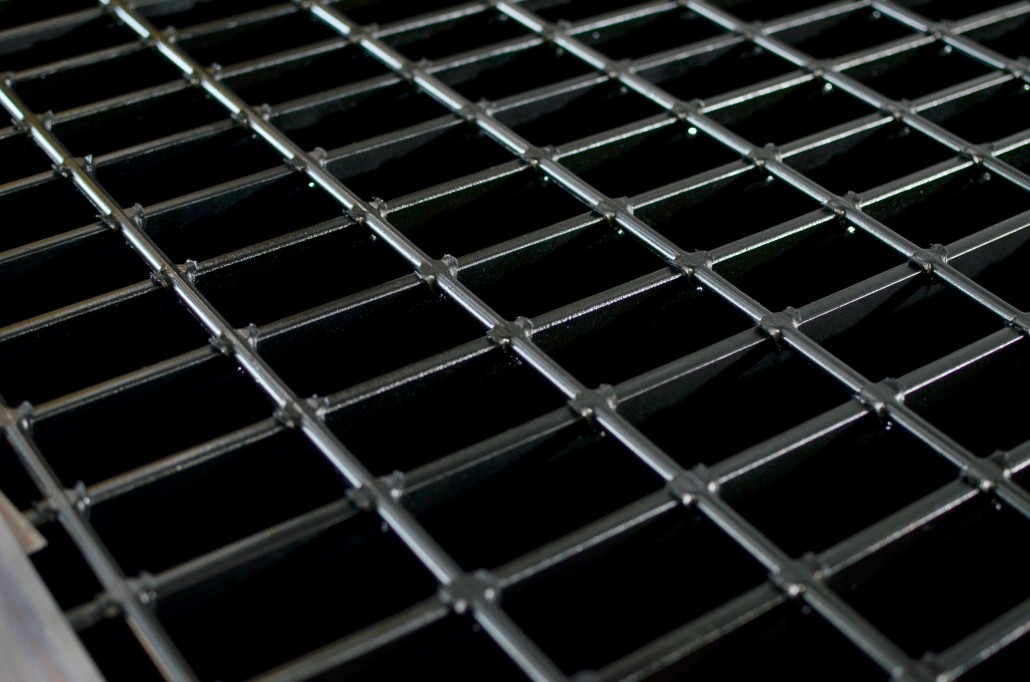

Also known as bar grating or just Grating, which is produced through the electroforged process. This consists in welding steel cross rods to perpendicular and equidistant bearing bars. This is achieved through high current and high mechanical pressure discharges, fusing the molecular elements of both components without placing filler material, as it occurs in the arc welding process. The forged welding process guarantees an homogeneous product of high quality and resistance.

The standard panel is normally made of 34 bearing bars.

Several Types of Steel Bar Grating exist, each of them satisfy different construction purposes:

- Heavy Duty Grating, commonly used at airports and in heavy transit locations.

- Stainless Steel Grating, it is mainly used in food industry plants and sulfate or acid environments.

- Galvanized Steel Bar Grating, ideal for any type of use, its finish ensures a longer lifespan of up to 60 years.

- AAR M-1003, grating used for running boards in the railroad industry. Manufacturer must fulfill certification.

- Architectural Grating, used in residential, urban and commercial projects as faÁ§ades, benches, balconies, fences, tree guards and as many other applications.

Quality and durability of the materials used in a construction project are important, but so is its design. Custom Fabricated Grating is an excellent alternative to ensure specific cuts and aesthetic, but also facilitates installation.

No matter what your project is, Steel Bar Grating is a good option to reduce costs and maximize durability due to the different applications that features. Seek a good installation avoiding The 4 most common mistakes in Steel Bar Grating Installation.

Take advice with the experts!

Español

Español